About the materials we use.

About the process of creating concrete lamps, or how did we start?

Concrete is our origins, that's where we started. We like simple, minimalist forms. This material seemed to us the ideal raw material; it is durable and can be used to create interesting shapes. Concrete is often - or maybe even mainly - associated with modern interiors, lofts and spacious spaces. In recent years it has experienced a real renaissance. Also in applied art, interesting objects can be conjured from it.

Concrete lamps of the company eight thirty are handmade

in our home "workshop".

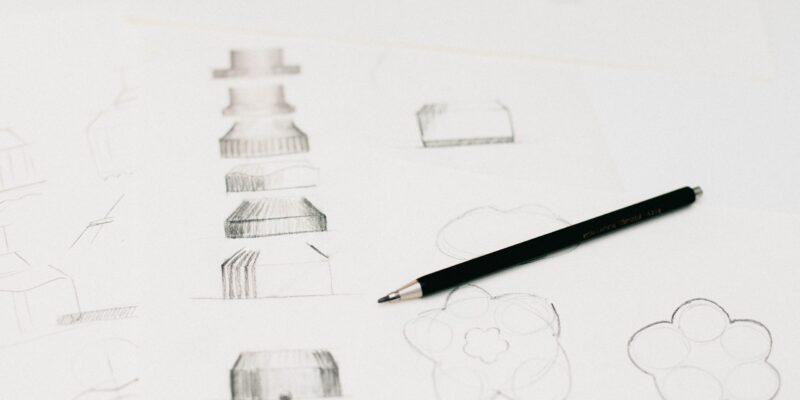

First the idea goes on the paper of a sketchbook. This is always the beginning of any vision. Standing, round, hanging or slender. We draw, revise and choose.

To get the designed model, we need to shape the concrete properly. We get the right look with silicone molds, which we prepare ourselves. We pour the mixture into them and.... we wait. The mineral material we use has the wonderful feature that it solidifies within one hour, but it takes a lot of patience for the lamp holder to dry completely. Then only a short sanding and part of the work is ready.

Each binding is slightly different in its texture. This is the result of the solidification process. Individual pieces are thus special and unique.

Concrete does not have to be gray. With the right pigments we can give it any color we want. A tinted binder, a striking cable and the right light bulb with a warm saturation of light make a concrete lamp can look interesting in almost any interior.

3D printing is a sea of possibilities acquired through modern technology and the knowledge of professionals. Combined with the creativity of designers, engineers and artists, stunning products are created. An example is the FLOWER lamp. The slight differences that occur during printing are natural and cause each element to gain its individual "character" with this.

The company's eighth-thirty 3D lamps are designed in a home studio, in Gliwice.

Sketch and study. Paper will accept anything - this is how we seek and create the initial design. We look for inspiration in nature, among design icons and in art.

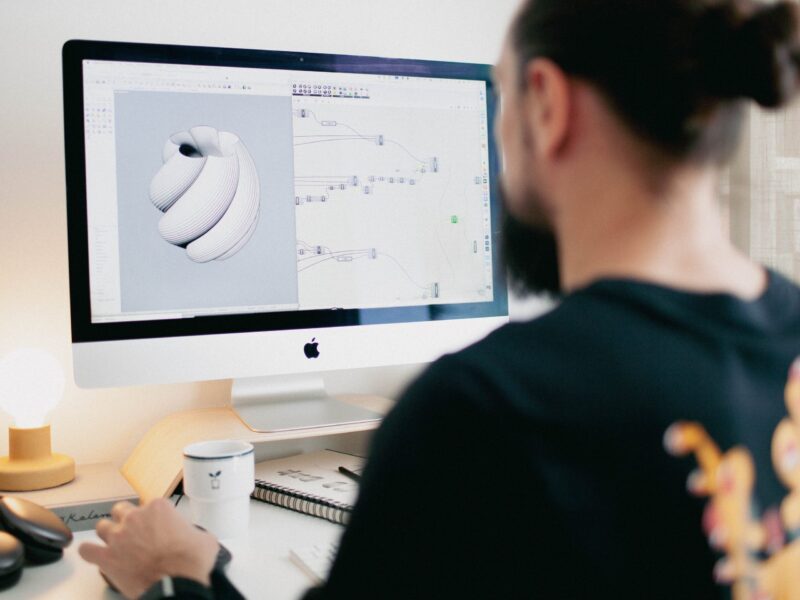

Digital design stage. Without a computer, not a move. You need the ability to use an advanced program and the ability to calculate accurately. This is the longest phase in the creative process. It requires patience, focus and knowledge.

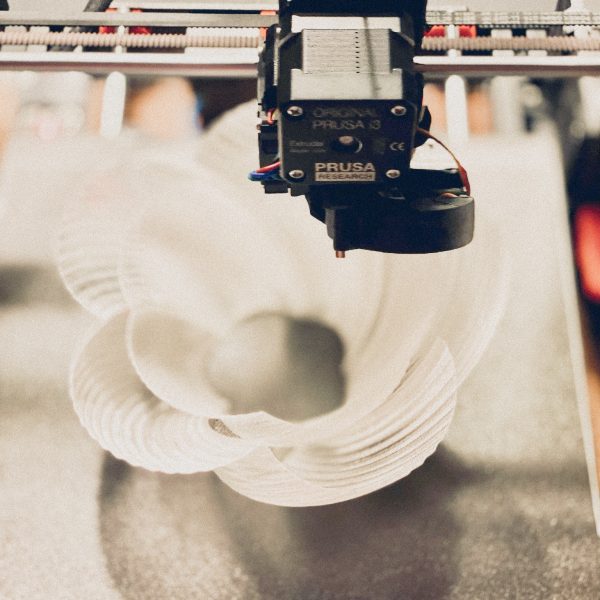

We are printing, that is, materializing a digital project.

It can be a stressful process. Not everything always goes according to plan. There are slip-ups, mistakes or technical problems. Designing and 3D printing is a constant learning and gaining experience. However, when the result is in line with the idea, then satisfaction is great.

We carefully check every centimeter of the product to make sure that the highest quality products reach our customers.

If the final product consists of several printed components-this is the case with the FLOWER lamp-we connect the individual components and make sure that everything "fits like a glove". We do not use any screws, rivets or adhesives.

From idea to product. Done! We put in your hands unique items created with attention to every detail. We believe that our lamps perfectly complement the arrangement of a space and give it a subtle glow.

Few words about materials we are using.

Filament is a thermoplastic material, which is most often used in the process of spatial printing using the melt deposition method.

In this method, the applied raw material is pressed through a special nozzle additionally heated to a temperature that facilitates its melting.

Although 3D printing itself is still considered a new technology, the aforementioned method was invented as early as the 1980s, and has been one of the most well-known ways of rapid prototyping since the 1990s.

We use PLA filaments, which are made from natural plastics, to make our lamps. Due to their easy shaping, they are the most popular among all 3D printing materials.

Creating new products should always be done with the future of our planet in mind. The materials we use are made entirely of biodegradable raw materials. No waste is generated in the process of constructing the lamps. Material from damaged prints can be reused. We source our filaments from Polish manufacturers.